When solutions aren’t on the shelf

Published on July 25th, 2018

At the upper-end of the competitive spectrum, the pursuit of improvement never ends. Critical to that is rigging systems in which the path toward improvement may not yet be paved. This report for Seahorse magazine details the path of one such situation.

“Design solutions often rise directly out of the feedback we receive from sailors who are competing at high levels and looking for that extra edge,” says Harken design engineer and small boat product manager Matt Schmidt. “The conversation begins with a simple question: What do you need to sail the boat faster?”

One of the sailors looking for answers was two-time Moth World Champion, US Olympic Nacra 17 sailor and engineering graduate Bora Gulari. “I was trying to help my Nacra crew deal with mainsheet loads in the most efficient way possible,” says Gulari. “As with a skiff they don’t get much of a break and the mainsheet load is typically higher on a catamaran, so my first response was “Let’s try to improve the mainsheet system.”

“The other thing was cleat adjustability,” he continues. “The increments in which you could adjust the cleat angle were too large, so it was really hard to get the perfect angle to use the mainsheet cleat well. It’s not super-important for the crew, because they always have their hand on the mainsheet, but at important moments in manoeuvres it helps the skipper’s boathandling to put the mainsheet in the cleat and get it uncleated too.”

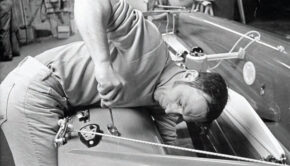

Back in Pewaukee, Schmidt and his team put their blocks on a test bench, measured the efficiency of the standard Carbo blocks and said, ‘OK, we can do better.’

“Pretty soon they came out with their first prototype,” says Gulari, “which was using standard steel bearings. As you can imagine, it did not last long but as soon as we started trialing, we said ‘We’re onto something here, what’s the next step?'”

The next step for Schmidt was to find the right materials. “We examined a variety of bearings and chose ceramic for the inner and outer race, and the ball bearings. The sheave is made from the same material used in Harken’s Carbo line of blocks.”

Gulari kept testing and feeding back. “We went through a couple of design iterations,” says Schmidt, “and once we were happy that the efficiency was going up we looked at the form to see if we could improve that in terms of the size, getting the blocks closer together, and aero too.”

The result, for Schmidt, is genuine incremental performance improvement. “Every feature we’ve designed into this product offers on-the-water benefits. Number one is efficiency. This system is easier to trim so the crew can save a fair amount of energy over a stock system.

“Elite sailors notice this right away. For a development partner who competed in the Florida 300 distance race it meant the difference between trimming the mainsail all day with one arm instead of two.

“The ease of trim also translates into smoother crew movements. For instance, in the Nacra 17, where most often the crew is the lighter, smaller team member, it doesn’t require legs or full-body lunges to get that extra bit of trim. This equates to less bounce and vibration at the mast tip.

“Second only to efficiency is the compactness of the system. This applies specifically to the Nacra 17, where the pin-to-pin distance of the mainsheet directly impacts the maximum mast rake. By closing that margin by 75mm and getting the top and bottom blocks to nest together more tightly we effectively give the skipper a tighter leech and the option to put that much more rake into their rig set-up when needed in heavy air.”

Schmidt continues: “The new cam arm adjustment offers infinite settings. We replaced the holes with a slider track that can be adjusted for an ideal lead. The cam arm assembly is contained too, so there’s no risk of losing parts in a quick on-the-water adjustment. The system is serviced with a single 4mm hex wrench. Easy, low-hassle.

“Development lasted about two years, but with many more iterations than in a normal commercial process. Eventually we had to have Bora commit to it in its then-current form for an important regatta. That was nerve-wracking!”

“The process was very smooth,” adds Gulari. “I’ve been lucky in terms of enjoying a very nice relationship with them, but they work with anybody who wants to work with them.”

We’ll keep your information safe.

We’ll keep your information safe.