How much do you know about rope?

Published on November 6th, 2014

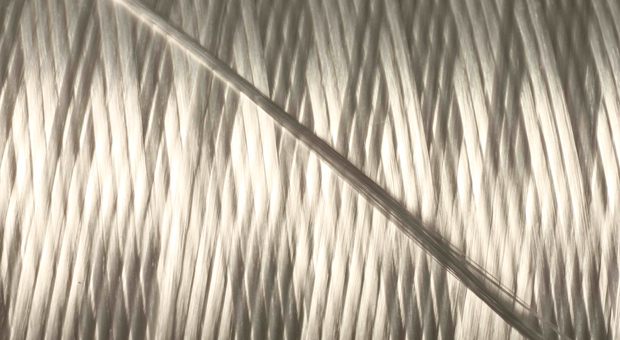

Dyneema® has become the ‘Gold Standard’ for performance running rigging. However, with new grades of Dyneema® being introduced and different treatments available, the decision as to which core is best can often be confusing. In this excerpt from Seahorse magazine, Marlow Ropes provides an update on the choices…

SK75 – for many years the strongest Dyneema® grade and the standard material that everybody understands. Thanks to new and improved grades, SK75 is being used less and less and is now not offered by Marlow.

SK78 – has become the standard grade used by Marlow and other reputable manufacturers. SK78 has the same strength as SK75 but offers significantly improved creep characteristics than its predecessor.

SK90 – launched in 2009 and offers approximately 10-15% strength improvement over SK75/8. However, SK90 only has the same elongation and creep characteristics as SK75. While still available, SK90 is now not specified by Marlow ropes due to the introduction of…

SK99 – the latest offering from DSM Dyneema® launched in 2013. SK99 has 20% strength advantage over SK78 and crucially retains the same elongation and creep characteristics as SK78 – outgunning SK90 on all levels! SK99 has an unmatched strength-to-weight ratio and has carved a niche for itself as the ultimate performance core material.

DM20 – has slightly lower tenacity than SK78, but has one major advantage in that it exhibits virtually zero creep. Used mainly for static load applications such as standing rigging.

Dyneema® exhibits creep, and it is important to understand how this affects a rope’s elongation characteristics. Creep can often have a negative effect on a rope’s performance and strength, when ropes are subjected to high loads for extended periods. Here Marlow explains…

– Initial loading will result in elastic extension. This is immediate upon loading and is immediately recoverable upon release of the load (elastic contraction).

– After the elastic extension of the initial loading the rope will experience what is known as viscoelastic extension. This is further extension over time and is fairly limited. Unlike elastic stretch, viscoelastic stretch will only recover slowly over time once the load is released.

– Finally there is creep, which is permanent, non-recoverable and time dependent. Creep occurs at the yarn molecular level when the rope is under constant load.

– Once the load is released and elastic and viscoelastic extension recovered the rope will ultimately have experienced an element of permanent extension. This is a factor of both creep and ‘bedding in’, which is when individual fibre components in the rope and/or splice settle into their preferred position when under load.

Complete report in Seahorse magazine.

We’ll keep your information safe.

We’ll keep your information safe.