PHOTOS: Construction timeline of the Volvo Ocean 65

Published on December 9th, 2013

A series of images to illustrate the construction timeline of the newly designed Volvo Ocean 65 that will compete for the first time in the 2014-15 Volvo Ocean Race.

THE MOCK-UP: Work starts with a full size model of the boat built out of wood. This interior mock-up is used to fit the different components and systems inside the boat and finalise design details.

THE PLUG: First the hull is built at Persico in Italy. A highly accurate milling machine carves out the plug from a big block of polystyrene. Then the hull mould is built on that plug.

THE HULL: Boat builders laminate carbon to create the outside layer of the hull thanks to a 12.5mm-thick mould. Once completed, the hull is cooked at 90° C for about seven hours. A sudden change in temperature could damage the hull.

THE LAMINATION: Once the lamination is complete, the hull is transported from Bergamo in Italy to Southampton in England to be assembled with the deck at the Green Marine boatyard.

THE DECK: Meanwhile, the deck is built at Multiplast in Vannes, France. Also made out of carbon fibre, it too is transported to Green Marine to be assembled with the hull.

THE BULKHEADS: In England, boat builders start working on the bulkheads, key components of the internal structure of the boat. In an effort to make the new Volvo Ocean 65 stronger and safer, it has eight bulkheads – that’s around double the average number in the Volvo Open 70 on the previous race.

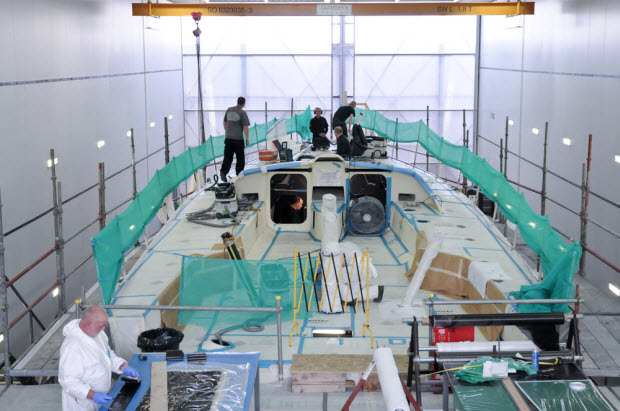

THE ASSEMBLY: Once the bulkheads are fixed, the hull and the deck are assembled. This picture shows the two components finally attached.

THE FIT-OUT: Boat builders are finalising details inside the boat – that’s the fit-out phase. Work inside the boat takes place in a very small and dark space.

THE PEOPLE: It takes 120 people working directly on the boat to build a Volvo Ocean 65 in seven months. A total of 36,000 man hours are required.

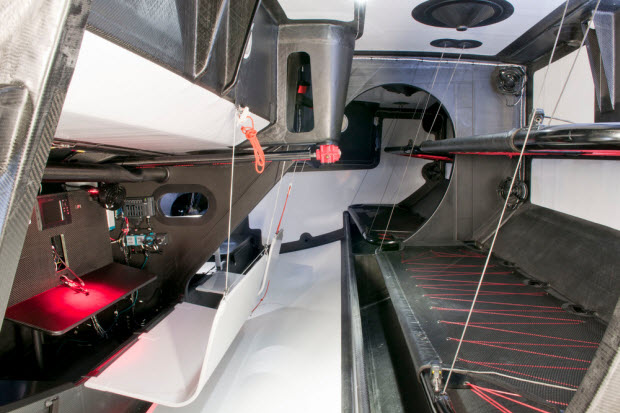

THE BUNKS: Inside the Volvo Ocean 65. On one side are the bunks where the sailors will sleep in four-hour watches.

THE GALLEY: View from the companionway. The galley (or kitchen) sits in the middle and two gas bottles provide fuel to heat the water to prepare the freeze-dried food.

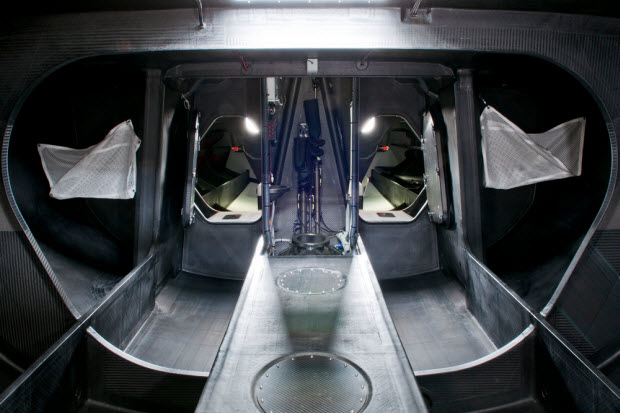

THE TOILETS: The interior of the boat from bow to stern. One can fully appreciate the carbon decoration with the full-carbon toilets in the middle.

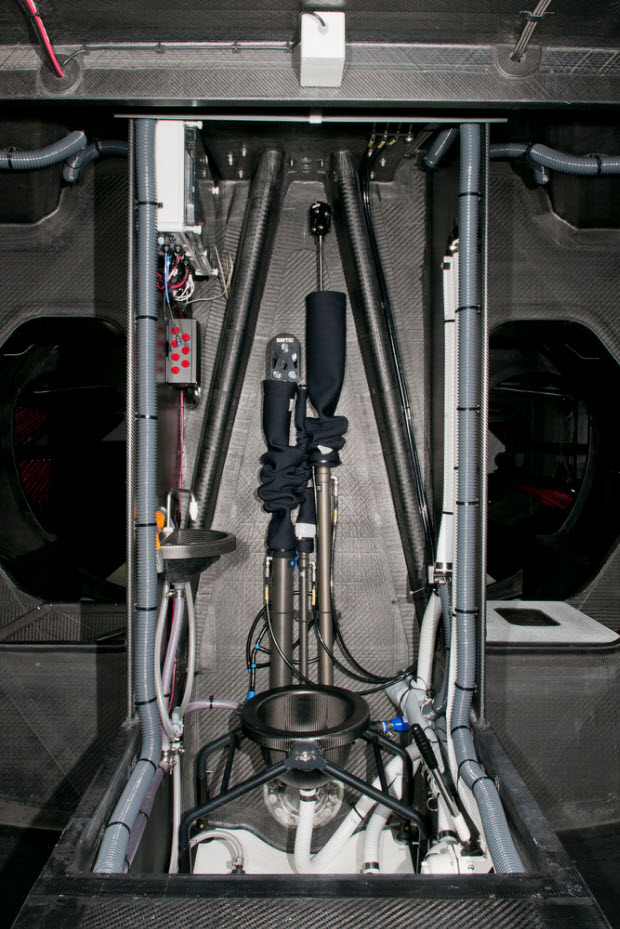

THE TOILETS: A close-up of the toilet.

THE BOAT: The completed boat at Green Marine.

THE PAINT: The boat is now fully assembled and all systems are installed – it’s time to paint in to the team’s colours.

THE KEEL: The keel is being fitted to the boat before it hits the water for the first time.

THE LAUNCH: A crane lifts the 12,500 kg boat to put it in the water.

THE STRUCTURAL TEST: Once in the water the boat passes a series of structural tests, the most impressive being the pull down test when the boat is heeled to 50 degrees to test the structure and the canting mechanism.

THE SAILING: The one-design Volvo Ocean 65 is now sailing – the all female Team SCA crew were the first ones to try their new boat out at sea.

We’ll keep your information safe.

We’ll keep your information safe.