Crossing Oceans with Zero Carbon Emissions

Published on January 4th, 2017

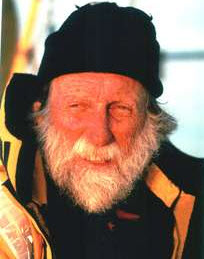

Sailing legend Donald Street has consumed more saltwater than most of us will ever sail on. He is a frequent contributor to Scuttlebutt Sailing News, sharing his extensive knowledge of weather and sailing equipment. Since the 1970s, he has been campaigning for more use of shaft driven alternators. Here he presents his case…

Some of the entrants in the Vendee Globe single handed round the world race have put their toes in the water by experimenting with a hydro generator that is mounted externally like an outboard to minimize the carbon imprint of their round the world race.

These units put out a lot of amperage with a small propeller and a low drag bracket but are easily damaged and it is not certain that they will put out enough amperage to satisfy all the electrical needs.

Since the Volvo Ocean Race and Clipper Round the World Yacht Race fleets are one design boats I feel these two fleets should jump in with BOTH feet and install a shaft driven alternator that would produce enough amperage to run all electrical needs.

There would be no need to run a generator and carry fuel which would save probably 1,000 pounds. If properly engineered shaft driven alternators were installed in the Volvo and Clipper boats, the round the world race could be done with ZERO carbon imprint.

The publicity generated would hopefully convince boats that cruise off shore to do the same thing, install a shaft driven alternator and cruise with ZERO carbon emissions.

There is nothing new about the idea of generating electricity from a freewheeling prop shaft.

I noted in 1975 in Ocean Sailing Yacht vol 1 (140,000 copies sold, copies still available via amazon) that the 36-foot double ended Block Island ketch Lang Zyne sailed around the world in 1948/49 with all electricity provided by a generator belted off the freewheeling shaft. This generator provided enough amperage not only to provide lights, but also ran the auto pilot and refrigerator.

Note that it was a generator, not an alternator. The refrigeration unit used much more amperage than a modern unit. Auto pilots in the 40’s and 50’s used huge quantities of electricity in comparison to modern units.

In my 1979 Ocean Sailing Yacht vol 2 (40,000 copies sold, again still available via Amazon), I noted the South African 45’ sloop Agwebe had an alternator running off a freewheeling shaft with a 18×10 prop that produced 30 amps at 5 kts.

Steve Dashew installed in a couple of his boats a wing shaft with a 12×18 prop driving an alternator that kicked in at low RPM’s an 80 lc electrodine. This is the type of alternator that are used on delivery trucks. This produced 15 amps/12 volts at 7 kts. At 8 kts it produced between 25 and 30, more amperage than needed to run electrics, refer, deep freeze etc. There were two problems; at certain speeds the prop would cavitate and create a lot of noise, and when batteries were charged the shaft would be locked and there was the drag of the 12 “ prop.

Steve was an American. He did not realize that at that time Watermota had a small engine that was direct drive to an adjustable pitch prop that could be feathered or pitch reversed. Had Steve installed the Watermota shaft, he would have had the perfect installation. The pitch could have been adjusted to give maximum amperage, once the batteries charged the prop feathered, no noise little drag.

Since the Volvo boats have a disappearing propeller and drive system, the wing mount is the way for the Volvo boats to go. With the money available they certainly could design VP prop that could be adjusted to obtain maximum output and feathered for minimum drag when batteries fully charged.

On the 56 ‘ ketch Lone Star built by Mashford Bros Crymell Cornwall (immediately across the Tamar river from Plymouth) in 1984, I urged the installation of a shaft generator as a backup of the engine driven alternator and the independent generator. The designer did not like the idea, but the owner and myself insisted that a shaft generator be installed. A shaft generator/alternator was installed and 32 years later is still working.

Lone Star which is now based in Pt St Louis Marina Grenada, has done a circumnavigation of the world and also a circumnavigation of South America, via Panama Canal and Cape Horn. Lone Star’s shaft driven alternator does not provide all the amperage needed but on passage cuts down the amount of time the generator has to be run.

Upon checking the installation in 2015, I realized that the alternator installed is relatively small. It only produces 8 amps at 24 volts, 192 amps per day. The torque produced by Lone Star’s 23” variable pitch prop is enough to run and alternator producing 20 to 25 amps at 24 volts. This would be more than enough to provide sufficient amperage for running all equipment including watermaker. Once the batteries were charged, the prop can be feathered to minimize drag.

While in Cowes in 1905 celebrating my boat Iolaire’s 100th birthday, the manager of Royal London YC in Cowes told me that he had sailed his 60’ schooner around the world with almost all the amperage needed produced by a shaft driven alternator. He felt that if the electrician was more enthusiastic (but he admitted it is hard to get enthusiastic about an installation that requires a lot of time head down and ass up in the bilge) the unit would have produced all the amperage needed to run his 60’ schooner.

Regarding prop to drive the system, use a feathering prop that when put in reverse will lock in reverse. Put the engine in gear in reverse. Hit the starter button, shaft will spin in reverse and lock the blades in reverse. Then put the gear shift in neutral, prop will free wheel driving the alternator. Once batteries are charged, put the engine in gear, in ahead, then hit the starter, prop blades will flip to drive ahead but since the engine did not start, and it is in gear, the blades will feather.

On a Volvo Ocean 65, and the speeds they consistently do, a wing mounted shaft driven alternator with a relatively small VP prop should easily produce 50 to 60 amps at 12 volts. On the 70′ Clipper yachts, belting an alternator off the existing prop shaft should be a relatively easy operation.

The props and shafts would all be standard, but let the crews work out what they feel is the best generating solution. With the money available to each team the R & D would develop rapidly.

If the Volvo fleet and the Clipper fleet would do what I recommend above, by the end of the next round the world circuits that the two fleets will do, all that could be learned about shaft driven alternators would be known.

The lessons learned could then be passed on to the general yachting public.

The average cruising boat with a shaft generator it would be sailing at lower speeds than Volvo or Clipper yachts, prop drag would be more important when going to windward than on the Volvo and Clipper boats. Cruising boats would not want the drag of the freewheeling prop so they would lock the shaft feathering the prop, minimizing drag when going to windward. With the wind abeam, or aft of abeam, the shaft driven alternator would produce more than enough amperage to satisfy all but the most electrically hungry boats.

With the wind forward of abeam, if one of the new high output but silent wind generators were mounted, it would certainly produce 10 or more amps at 12 volts. Thus 240 or more ampere hours a day. This is ample for all but the most electrically hungry boats.

With a combination of shaft driven alternator when wind is abeam or aft of abeam, and wind generator when wind is forward of abeam, the ocean cruiser could cross ocean leaving a ZERO carbon imprint.

However, this will not happen unless the Volvo and Clipper yachts popularize the idea of shaft driven alternators by installing them on their boats.

Looking at the difference in cost between the normal alternator, and the fully marinized one I would recommend buying two normal alternators. When the first one starts giving trouble remove and discard it and install the replacement.

Install a feather prop. The difference in drag between a feathering and folding is infinitesimal. On a feathering prop, when put in reverse, the blades flip so the proper side of the blade is working increasing backing power to between 50 and 75% over a sold or folding prop. Plus the good feathering props the pitch can be adjusted without disassembling the prop. It can be done in the water by a driver.

Every HONEST marine engineer admits setting the pitch for maximum efficiency given prop size, engine size, reduction gear and hull design provides so many variable that prop pitch is a bit of a guestimate. The only way to obtain maximum efficiency of a propeller is to do speed runs with different pitch setting until you find the best setting.

Put the engine in reverse, then neutral, prop locked in reverse, charge batteries. Once batteries charged hit the starter button with the engine in ahead, prop will unlock and since engine not running will feather.

As stated in the beginning of this section, when on passage, there is absolutely no reason to run an engine or generator to charge batteries.

A good wind generator will produce all or most of the amperage needed when the wind is forward of abeam. When the wind goes aft of abeam the shaft generator will produce all the amperage needed.

If the Volvo and Clipper round the world racers were required to generate ALL the electricity they need from wind and water, and the ARC gave a substantial prize for the first boat to finish on corrected time that generated all their electricity by wind and water, with the development money available to competitors, the efficiency of shaft generators would skyrocket.

If all the above is done, I am sure that five years down the line, off the shelf shaft generators would become available. If this were to happen, I am sure that on passage very few yachts would be running their engines to generate. Boats would use shaft generators when sailing down wind and close reaching, wind generators when beating to windward.

Sailors would be doing their little bit to minimize global warming. Sailing would be more pleasant with no generator noise or exhaust fumes to smell.

We’ll keep your information safe.

We’ll keep your information safe.