No limits to rigging refinement

Published on August 2nd, 2019

Mark Wiss, Director of Global Grand Prix and Custom Yacht Sales at Harken, provides words and imagery of how rigging has evolved at the pointy end of the sport.

Mark Wiss, Director of Global Grand Prix and Custom Yacht Sales at Harken, provides words and imagery of how rigging has evolved at the pointy end of the sport.

If it’s been awhile since you took a walk down the dock and looked carefully at the decks at any Grand Prix big boat event, you might be surprised at what you see. You’d see much less on deck than what you would have seen even five years ago.

Boats like the TP52, PAC 52, any Fast 40+ design, and even the Maxis and Centros have gotten so refined that literally everything not required to be at hand on deck has been eliminated.

Many of these classes are designed to thrive on the courses they sail most all the time (in-shore or coastal windward-leeward tracks), and so some of the equipment required to reach or change sails during legs has been eliminated. The result is a beautiful, minimalist, purpose-built look that echoes what happened in auto racing over the last 50 years.

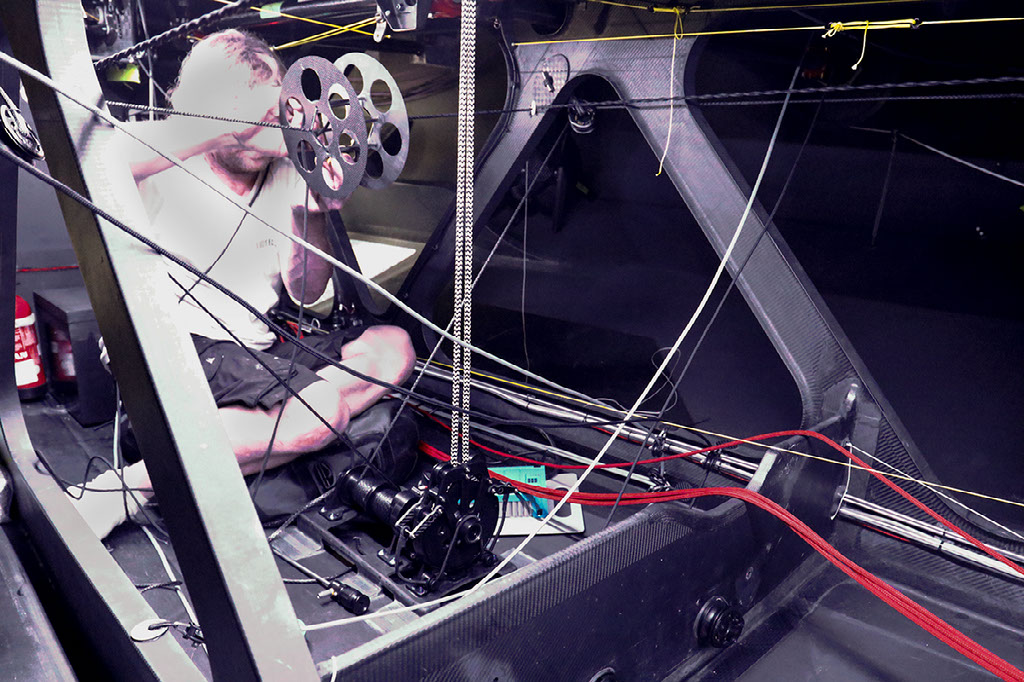

Concurrently, more performance adjustment than ever is happening below deck. What lives down there? Hydraulic pumps to modulate rig tension, backstay deflectors, vangs, etc. In more and more cases, beginning even on some boats under 70 feet, sheets are being managed by captive reel winches which also live below deck, resulting in less and less line piling up in the cockpit.

Control systems like cunninghams, fore and aft jib car adjusters, inhaulers, and travelers are now rigged in cascading purchase systems with startlingly small diameter line.

Control systems like cunninghams, fore and aft jib car adjusters, inhaulers, and travelers are now rigged in cascading purchase systems with startlingly small diameter line.

On these multi-part but very free-running purchase systems, Harken Fly blocks are appearing more and more. These are very small but designed to be very strong blocks that you might see on a Moth vang, and they are also all over the place down below on a 72-footer.

Moving systems below deck saves wind resistance and frees the crew from the need to navigate around extra control line as they move through tacks. What’s more, some deck designers are recessing titanium V-sheaves in the aft decks to bring kite sheets below deck. They come back through the deck to be trimmed, but they spend part of their journey down there in the dark.

Also on more and more race boats, you’ll come across a ‘string drop’ system that brings the kite back aboard as quickly as the crew can turn the pedestal handles. Having a system like this is a real weapon, allowing tacticians to wait until the last minute to pick a leeward gate or establish an tactical overlap. And freeing crew for other tasks…like hiking sooner.

Harken makes control boxes that shift the pedestals and handle functions from sheet winches, to the reel that rips the kites in—without ripping sails in the process. These systems have become more sophisticated and reliable in the past several years which has fueled their broader adoption. Be sure to check out a video we did a couple seasons ago that shows how well these systems work.

I’ve said this before, but I’m going to say it again here; it’s true, Harken doesn’t just make products for racers. We make great products for all kinds of sailors. But in my job, Harken definitely makes products for racers—and the next time you’re below deck on a Grand Prix rocket ship you’ll probably see a bunch!

We’ll keep your information safe.

We’ll keep your information safe.