America’s Cup: The making of the AC40

Published on January 25th, 2022

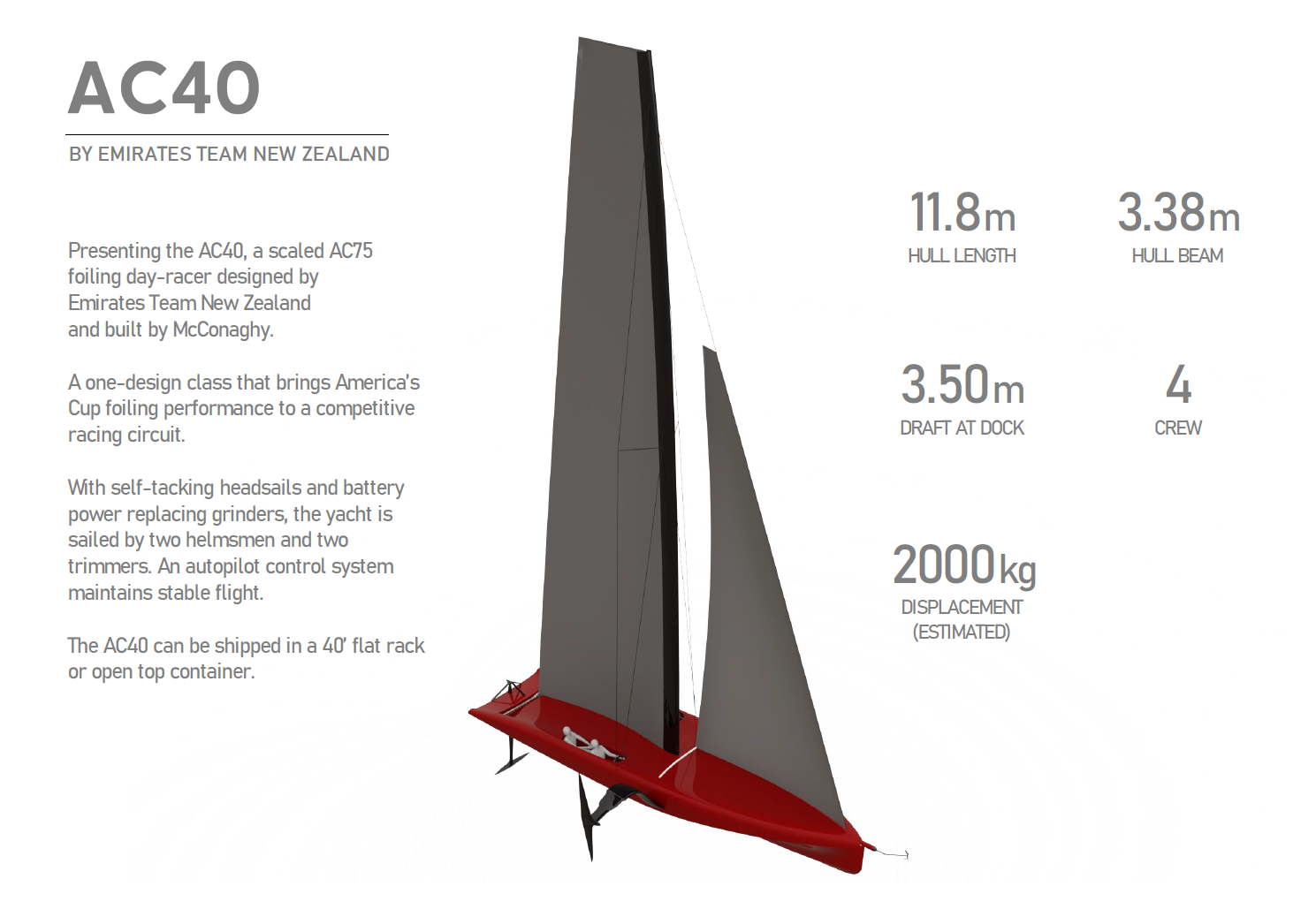

The Protocol of the 37th America’s Cup revealed that teams would compete again in the AC75 that was used for the 2021 event, but that a new AC40 one-design class would be used for testing and training as well as the preliminary regattas.

The intent is for there to be up to three Preliminary Regattas, with the first two raced in AC40s and the last one at the Match venue in AC75s. The AC40s would also be used for the Youth America’s Cup as there was in Bermuda in 2017, along with the first Women’s America’s Cup.

The New Zealand defender has taken on the development and production of the AC40 and offer this update from their Auckland base on January 26, 2022:

Just over 11 months since Emirates Team New Zealand’s AC75 ‘Te Rehutai’ crossed the finish line to claim the 36th America’s Cup, its younger sister class – the AC40 – is already in production.

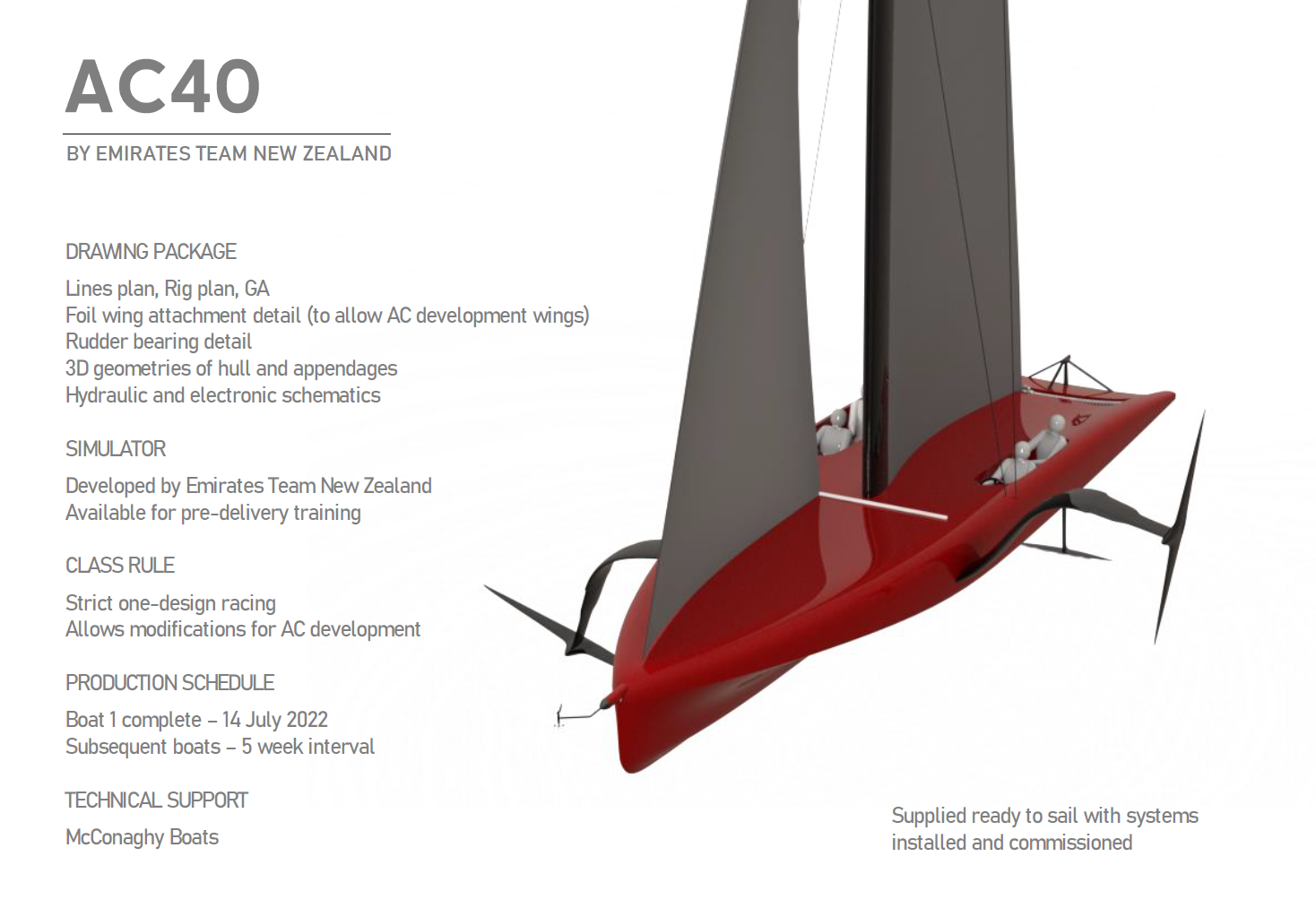

While much of the world was having a well-earned break during the transition from 2021 into 2022 the 7 axis CNC machine at McConaghy Boats production facility was working 24/7 carving out the tooling for the hull of the new class.

The AC40 hull shape is based on that of Te Rehutai – but is already a generational step forward incorporating a number of developments learned after the completion of AC36 last year.

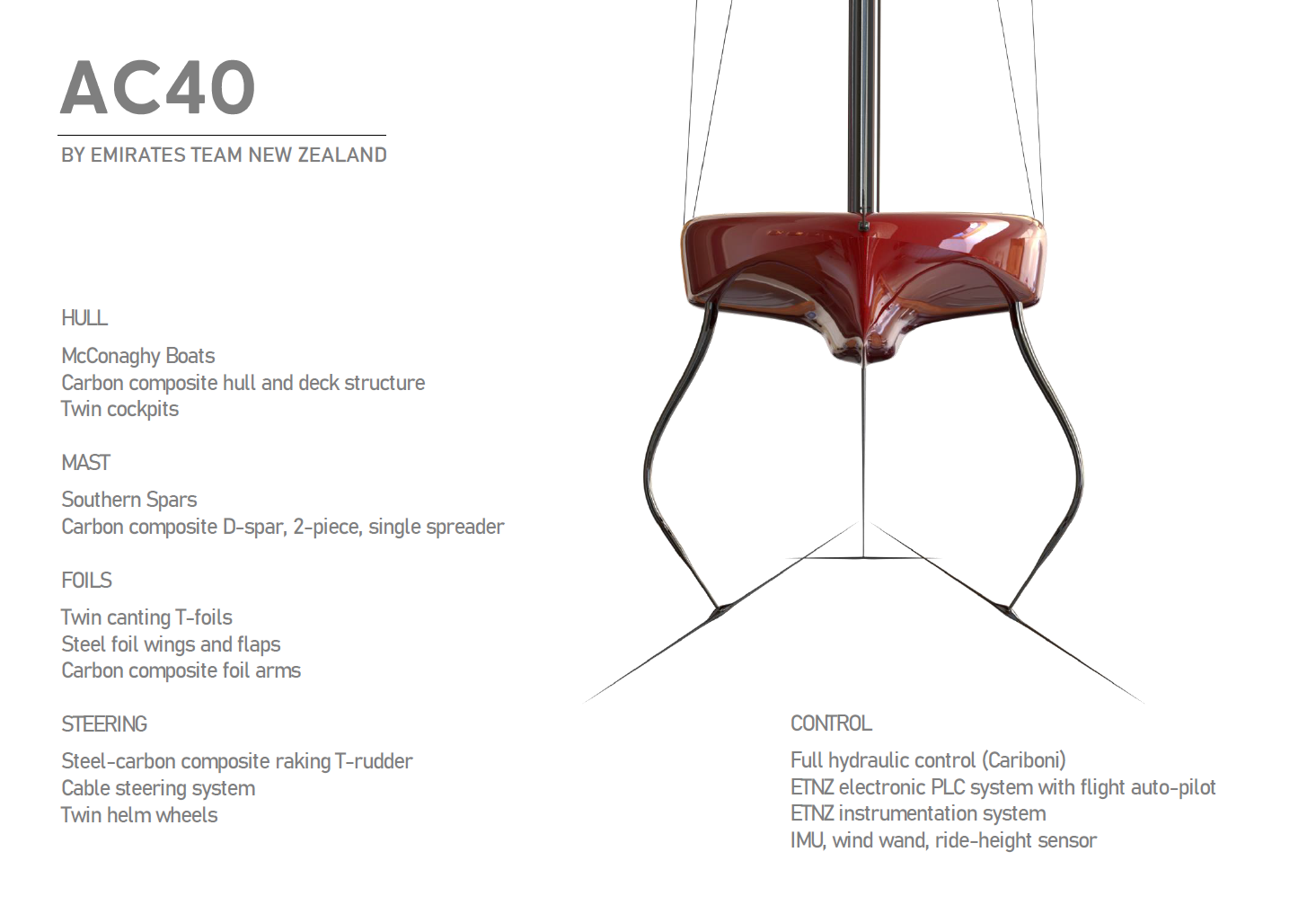

In usual America’s Cup fashion, the AC40 design and production timeline has been highly condensed yet achievable due to a global collaboration led by Emirates Team New Zealand design team with Dan Bernasconi and Richard Meacham central to the management of the production process with Mark Evans Group Managing Director of McConaghy Boats.

“While the genesis of the AC40 project comes from the familiar design and innovation of the people within the Emirates Team New Zealand design department, we have really had to push the limits by utilizing a combination of the best of the New Zealand Marine industry as well as key offshore partnerships,” said Meacham.

“Specialized elements like the rigs are being built by Southern Spars and the boat building talent we have at the ETNZ build facility are producing the foil arms. We also have a great partnership utilizing the production power of an organization like McConaghy Boats in China for the hulls, decks, and fit out as well as North Sails Marine group with the aero package.”

McConaghy Boats has been building composite race boats with leading construction technologies for over 50 years across a range of classes from maxis like Wild Oats (the most successful yacht in the Sydney Hobart race), all the way down to foiling Mach 2 Moths and Waszps.

But for now the focus is firmly on rolling out the fleet of AC40s. “Currently there are already eight AC40s under order with McConaghy’s, with teams lined up awaiting possession,” said Meacham. “We have a world leading marine sector here in New Zealand, but like so many industries there are labor resource constraints, so without partnering with McConaghys and utilizing their production capabilities, we simply would not be able to fulfill the orders in time.”

The first AC40 is expected to be ready to be shipped from the McConaghy facility in July of this year to the Emirates Team New Zealand base in Auckland for its on water commissioning in August. And each successive boat will be rolled out in five week increments thereafter as the Challenging teams take possession and prepare to hit the water where the performance across with wind range is estimated to be quite exceptional for a 40-foot boat.

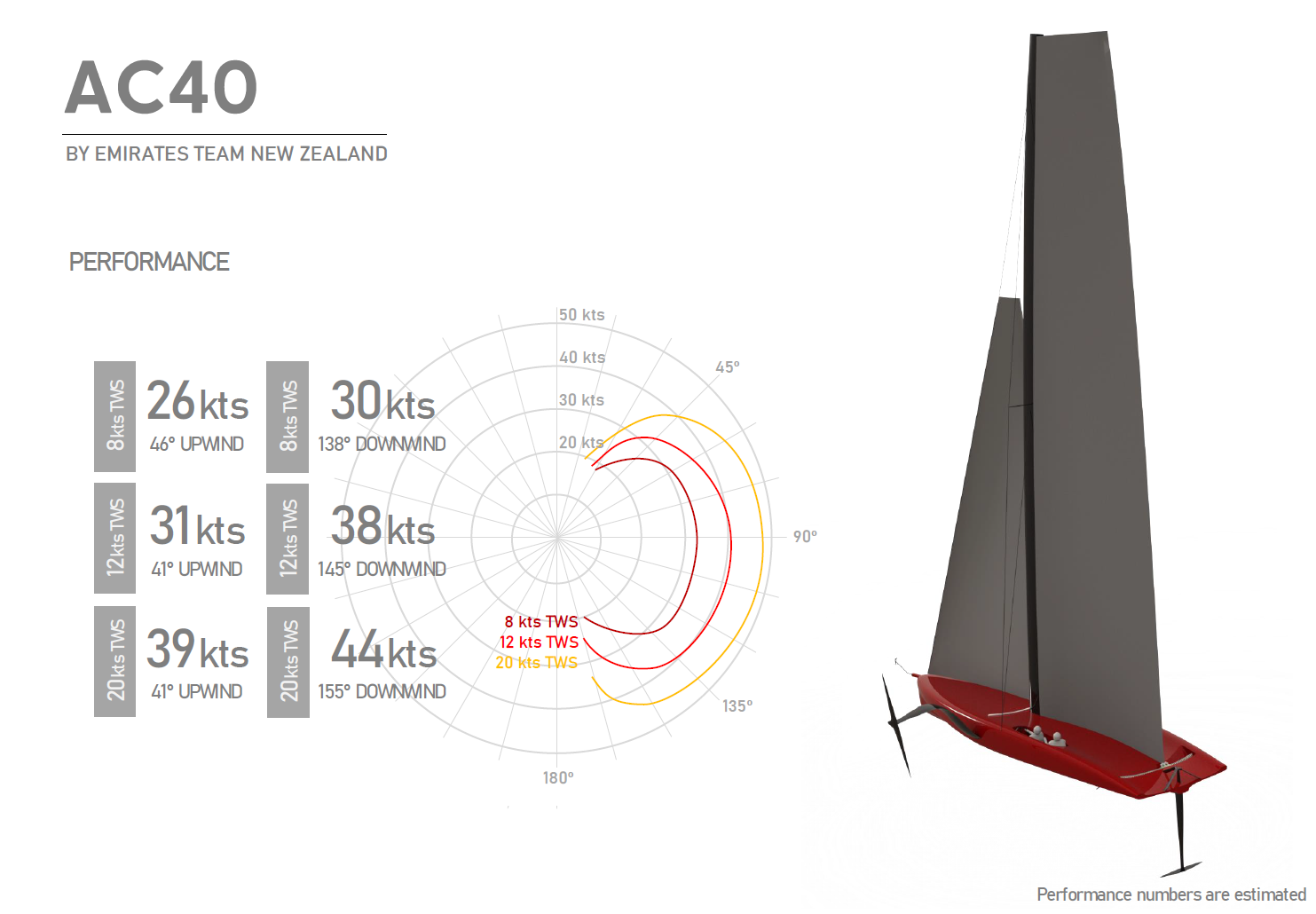

In light winds, the AC40 is expected to be able to sail at up to 26 knots at 46º upwind and 30 knots boat speed at 138º downwind. At the upper limits of 20 knots TWS, the boat speeds are expected to escalate to 39 knots upwind at 41º and 44 knots at an angle of 155º downwind.

Due to the AC40 being a ‘production boat’, the process has been a bit different to usual for Head of Design Dan Bernasconi: “Normally during the build of an AC boat, the design team has a bit more time to develop and finalize the hydraulics, electronics, and systems, but because the production process is so rapid in this case we have had to finalize a lot more of our designs in respect to those areas up front and make sure they are spot on.”

While the America’s Cup teams will be using their AC40s for testing, development, Match race training, and preliminary events, they will be used for both the Women’s and Youth America’s Cup’s as a key tool for creating the pathway into the America’s Cup for women and the next generation of foiling sailors. This pathway made all the easier with the added benefit of the availability of the AC40 simulator developed by Emirates Team New Zealand for pre- delivery training.

As a further step on from this, the AC40 and the simulator will be available to private owners, many of whom are the backbone of high-performance grand prix circuits already and could be looking for a new challenge in a dynamic boat that is right up there in terms of performance close to that of the AC75 America’s Cup powerhouses.

“There is even the possibility of private owners having a long-term ambition to race, but initially wanting to give a prospective Youth or Women’s AC crew a leg up with their campaigns by buying one early as well,” said Meacham

“So, despite the pressure of design and pushing this all along, it is exciting to see the moulds completed and production underway on a class of boat that will cover a wide range of use cases.”

Following the publication of the AC37 Protocol and AC75 Class Rule on November 17, the entry period opened December 1, 2021 and runs until July 31, 2022, but late entries for the 37th America’s Cup may be accepted until May 31, 2023. The Defender is to announce Match Venue and approximate event dates on March 31, 2022. – https://www.americascup.com/en/home

We’ll keep your information safe.

We’ll keep your information safe.